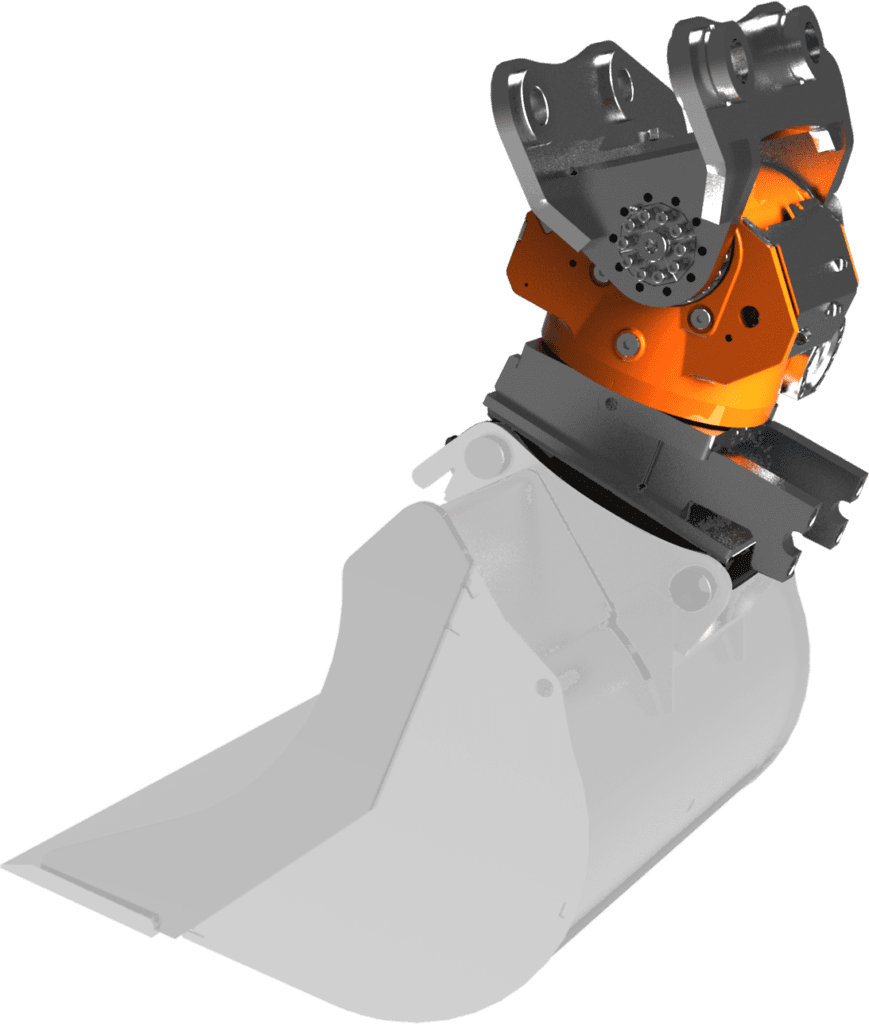

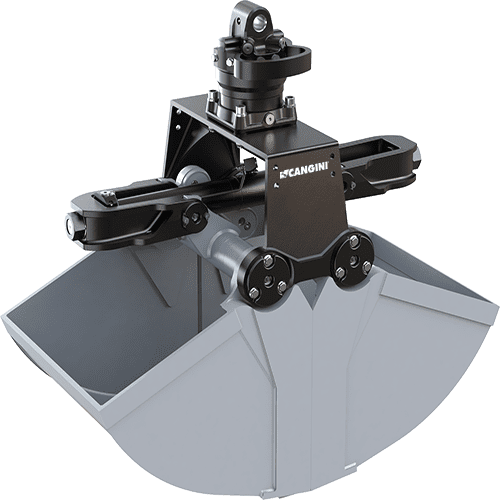

Screening bucket VRC

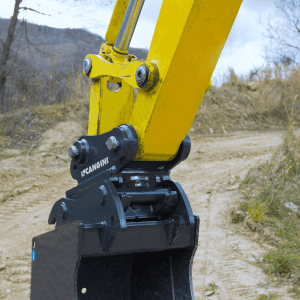

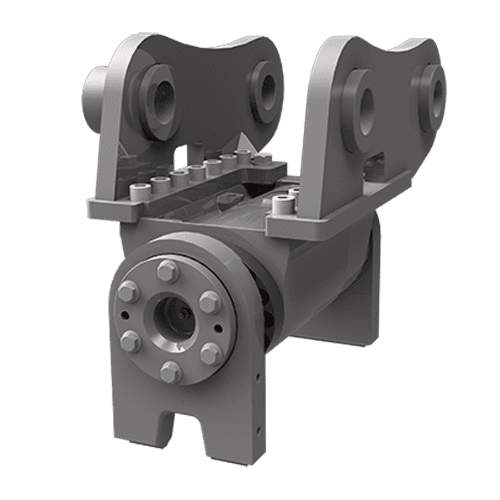

- Attachments for Excavators, Backhoe Loaders, Excavators

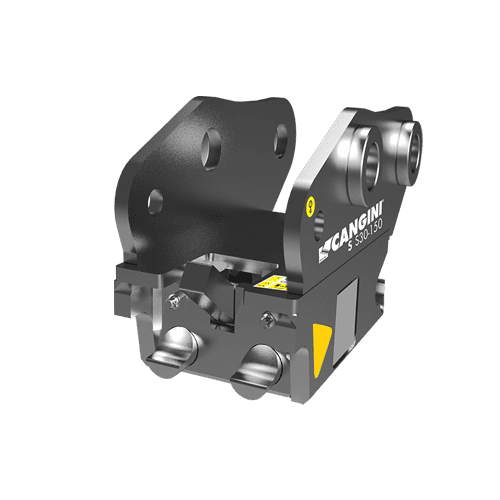

The VRC screening bucket is the result of careful analysis by our R&D department, combining innovation and high productivity.

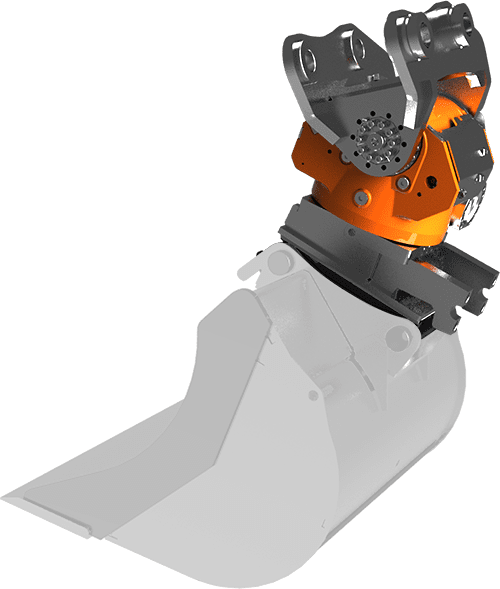

The VRC screening machine is designed for sorting and separating various materials resulting from demolition or excavation directly on site.

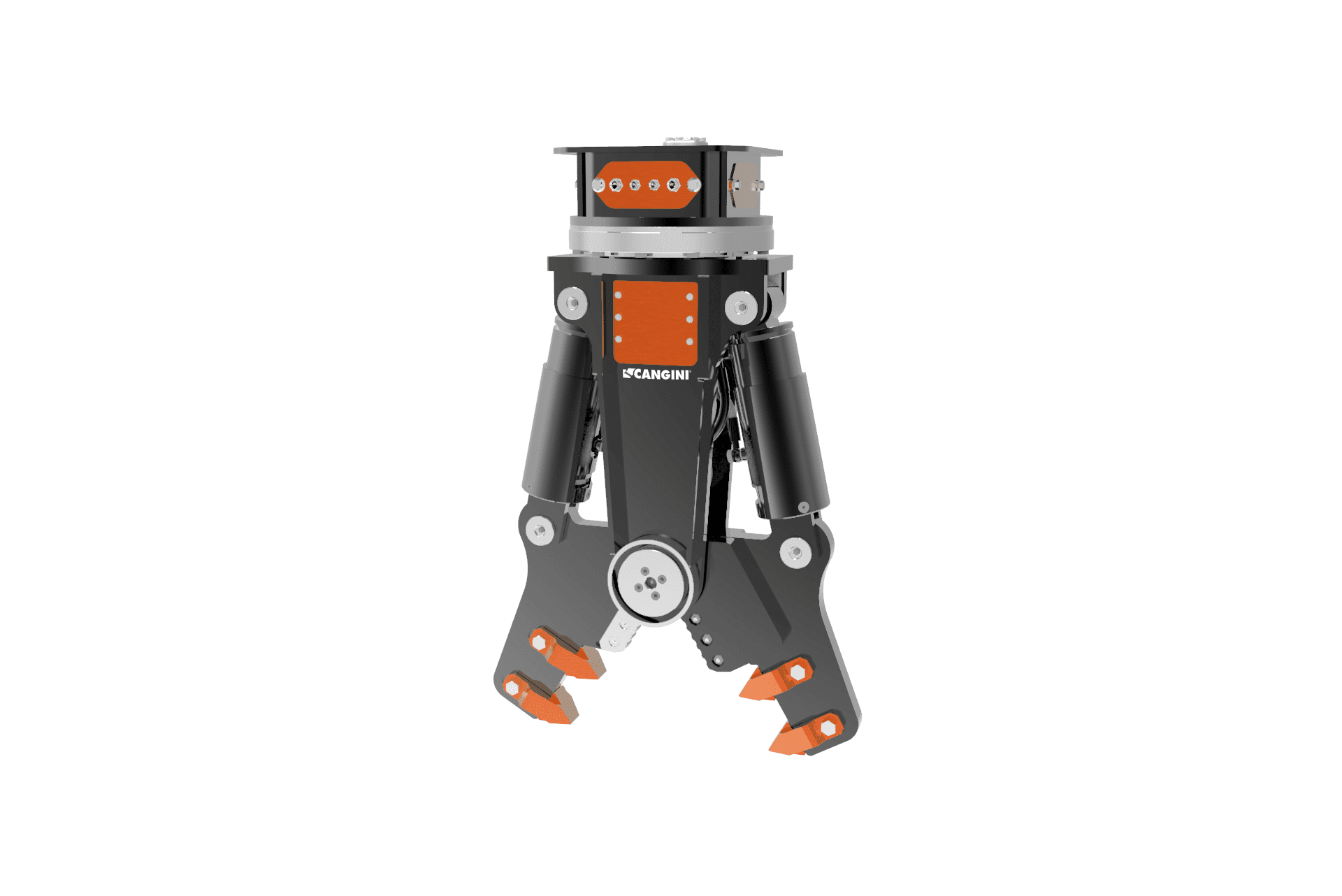

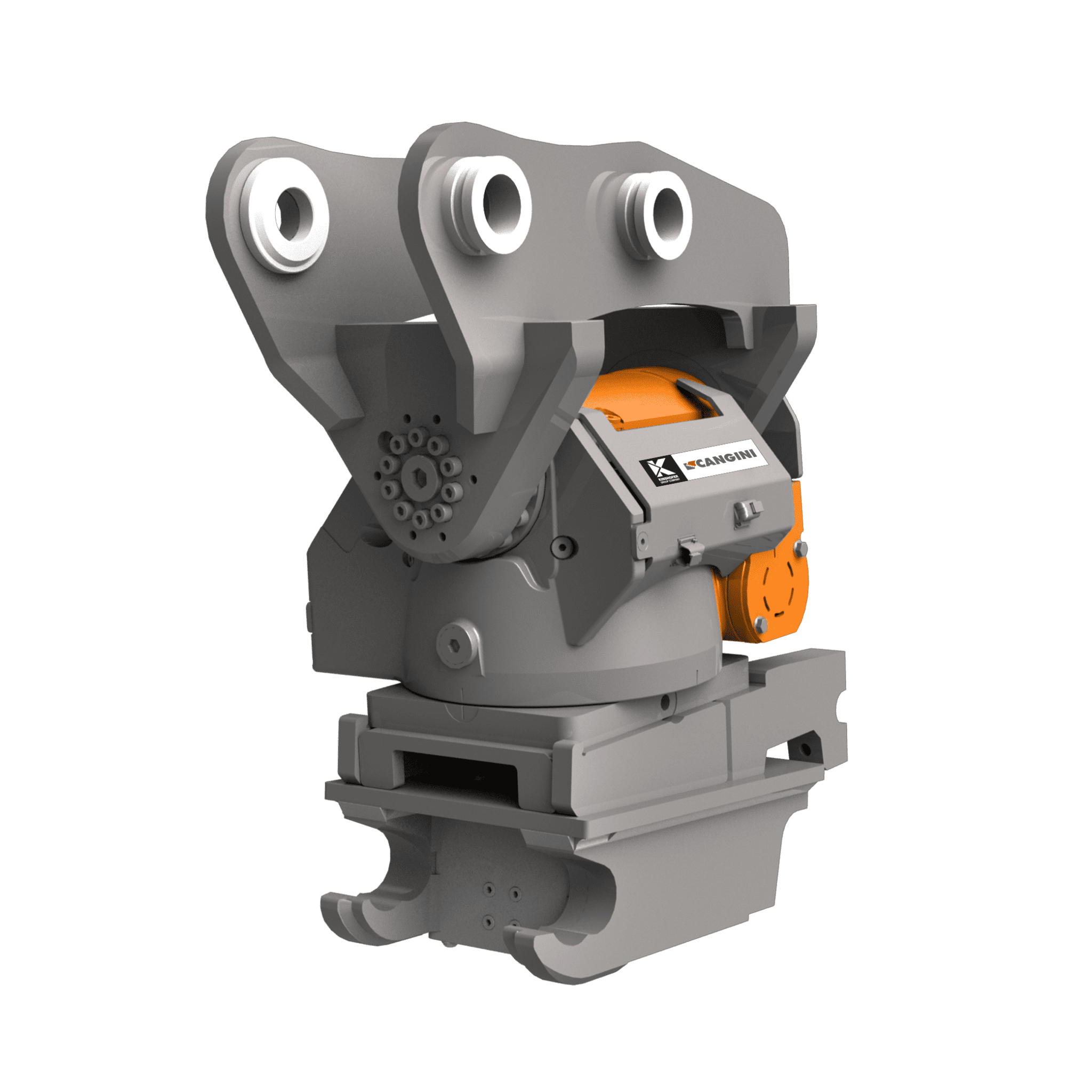

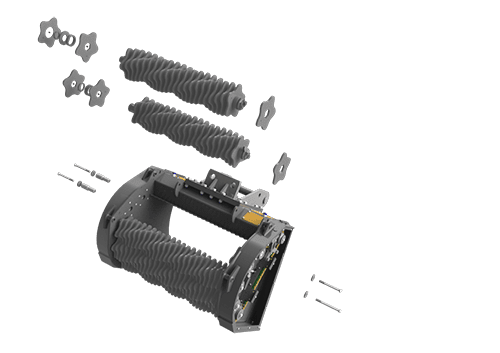

The VRC Cangini screening bucket is distinctive for its high productivity due to a high number of shafts (in each model a minimum of 4) composed of easily replaceable discs and positioned in an arc to increase the screening area, not flat like common screening machines on the market.

Even the smallest model has at least four screening shafts arranged for higher output per hour.

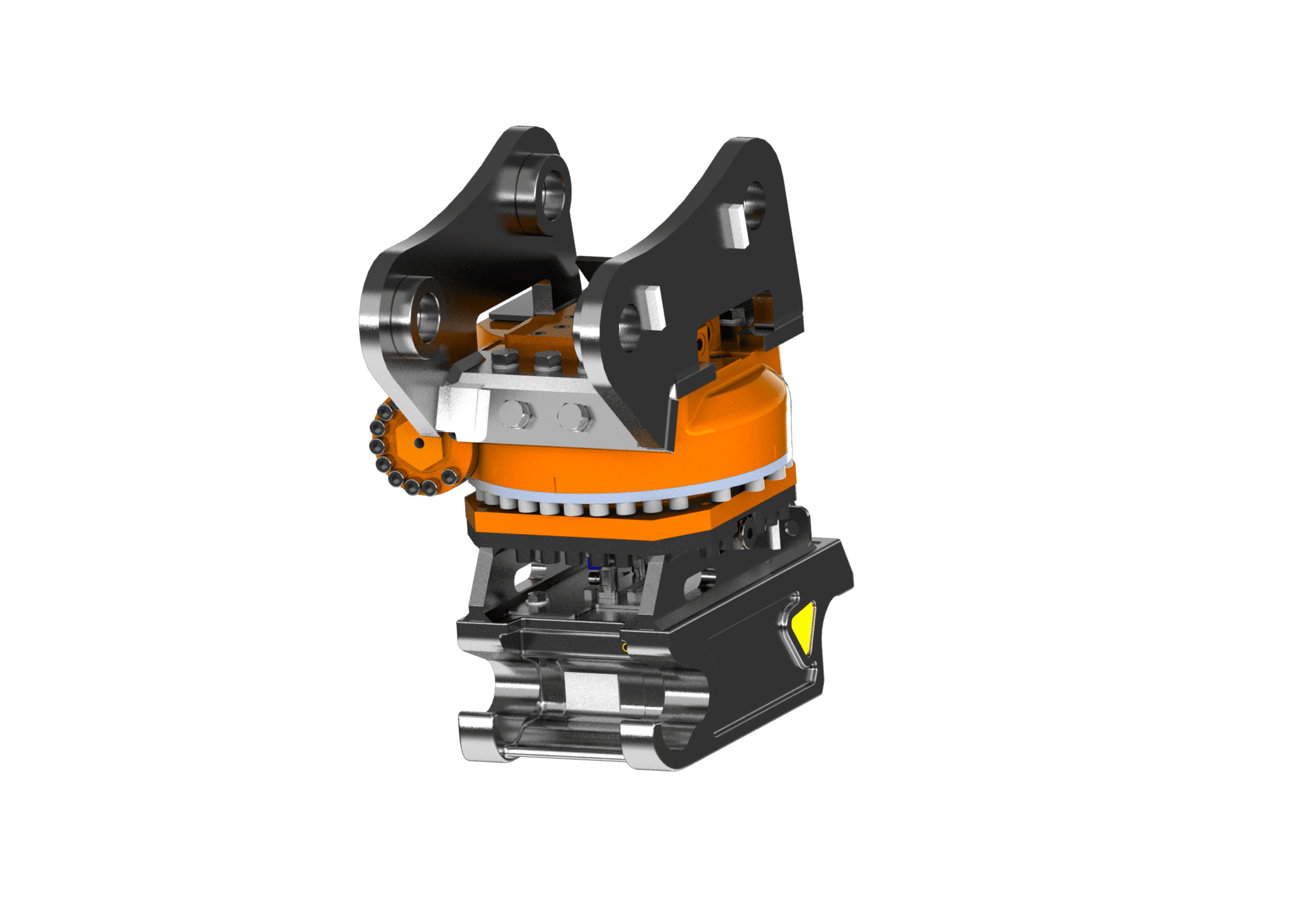

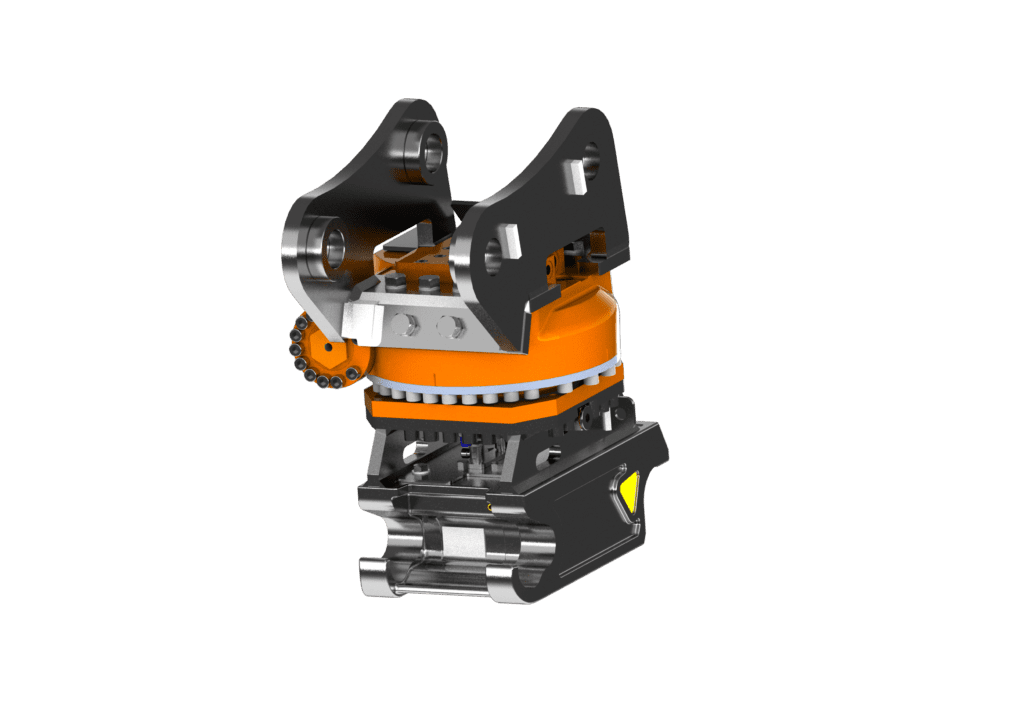

In addition, the VRC screening bucket, thanks to its toothed profile, allows for easy loading of the material to be screened. The thickness of the material to be selected can vary from 0-20mm to 0-35mm.

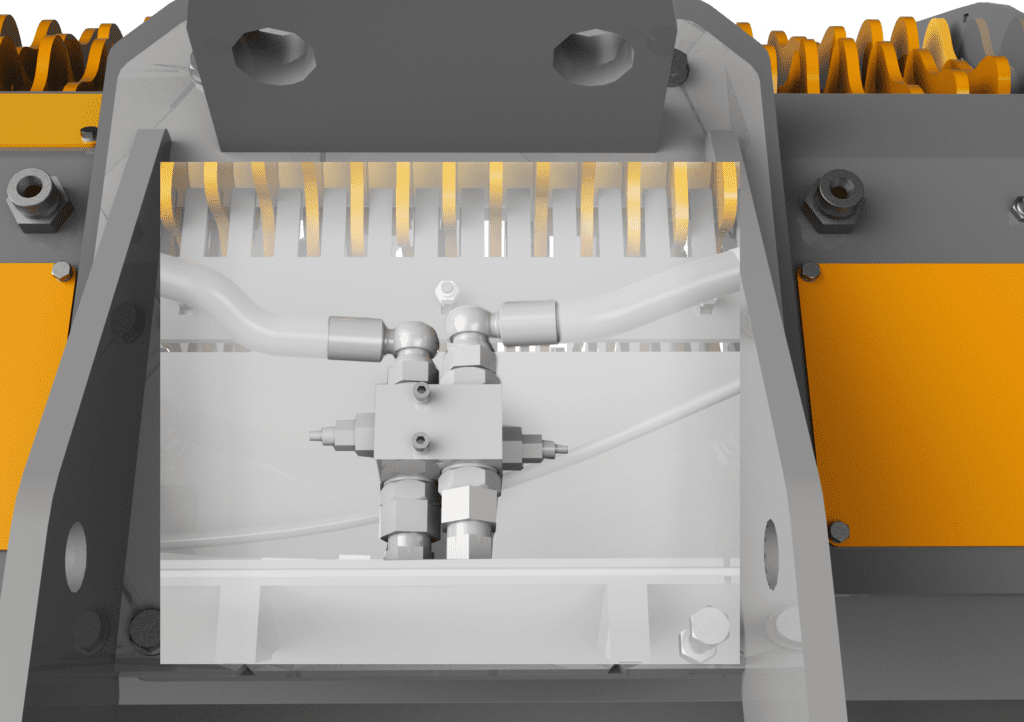

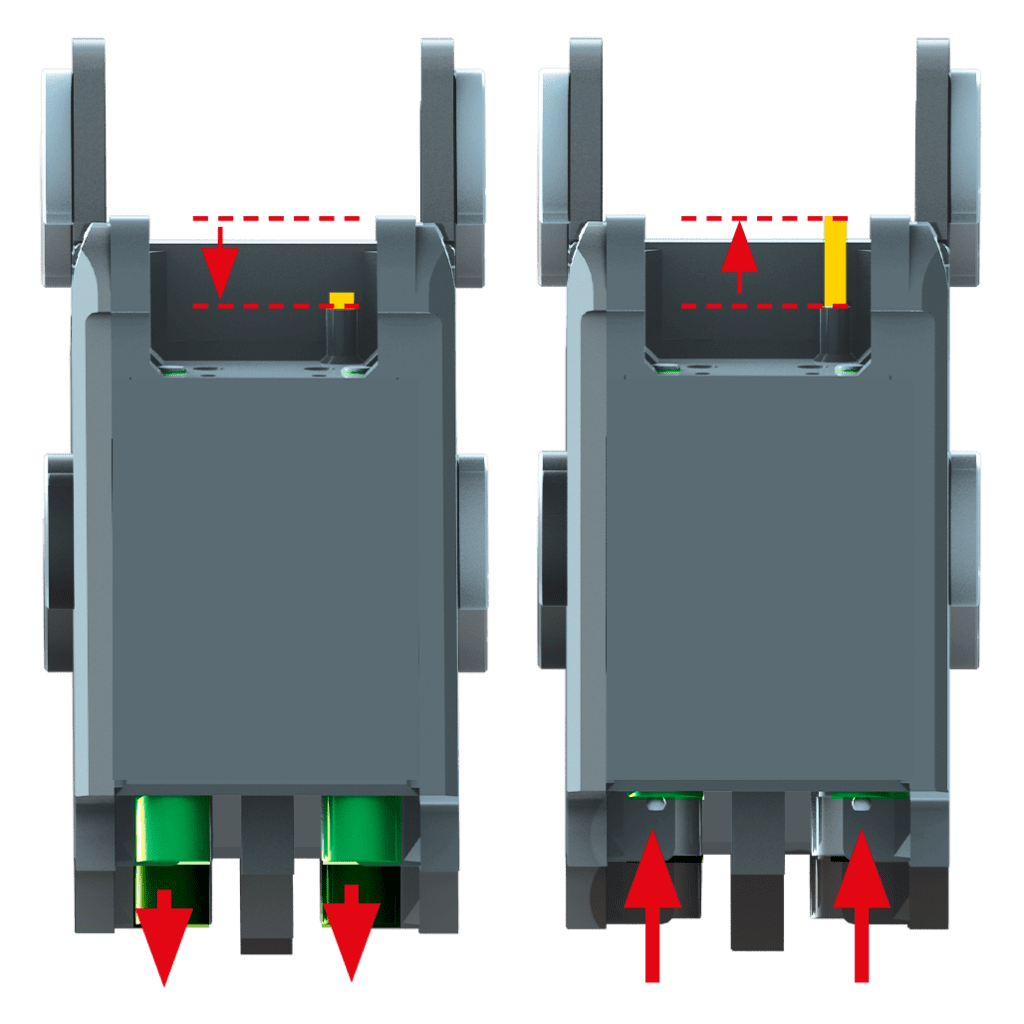

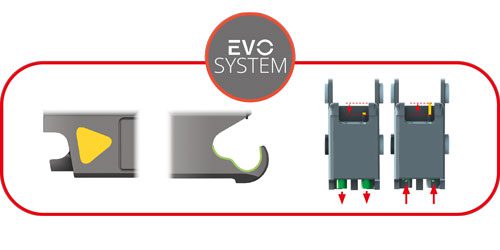

Screening machine maintenance is even easier thanks to:

- Automatic chain tensioning

- Bearings centralized greasing

- Easy replacement of the single shaft

Available in six models for every type of excavator, mini excavator and backhoe loader from 2.5 ton up to 22.0 ton.

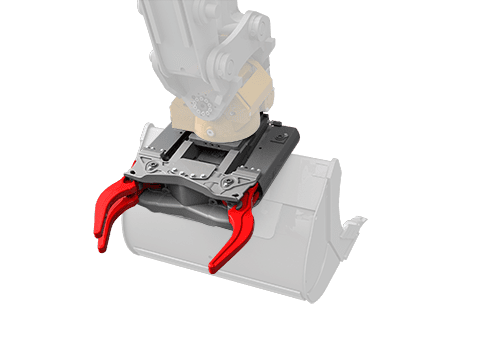

Easy of use

The bucket has centralised greasing of the bearings as standard, which facilitates product maintenance.

Fast maintenance

The screening shafts are positioned to increase the screening area and the discs are individually replaceable.

Long Working Life

The safety valve protects the motor from pressure peaks generated during operation, giving it a long service life.