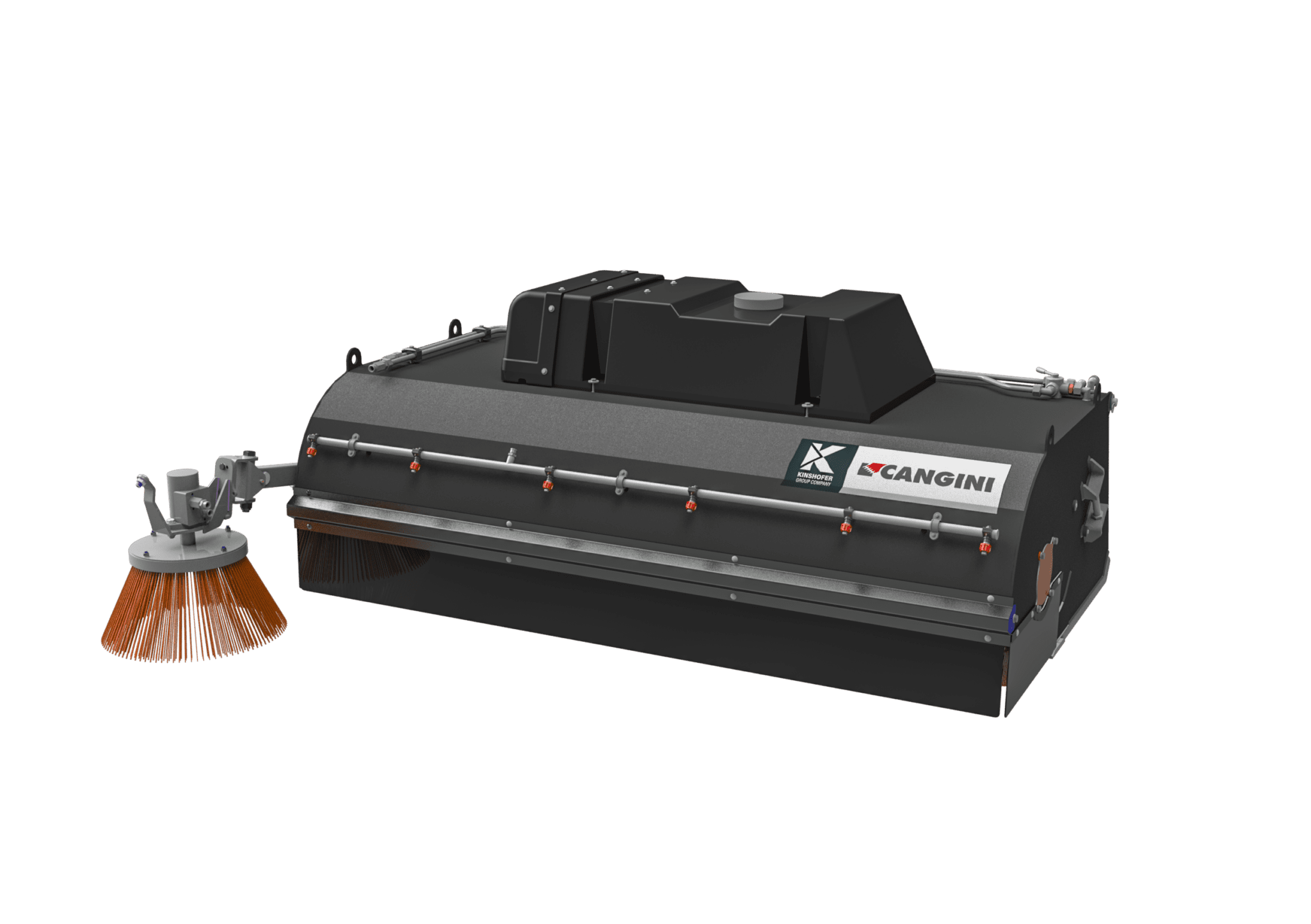

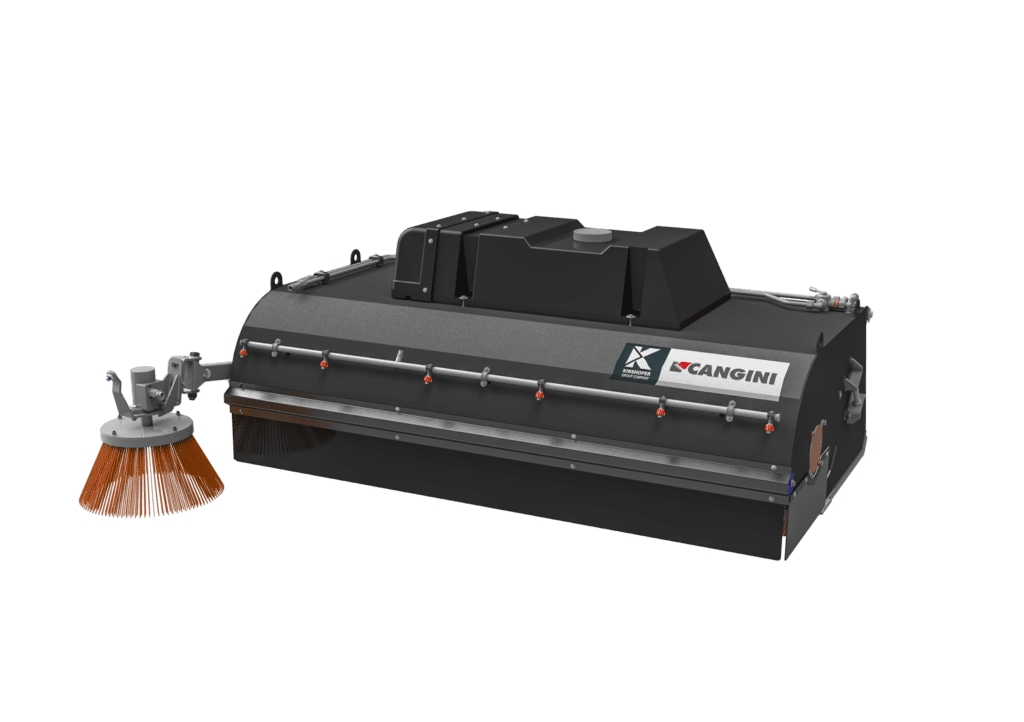

SWEEPER BUCKET 2.0

- Frontal Attachments, Skid Steer Loaders, Telehandlers, Wheel Loaders

The ideal equipment for deep cleaning of any surface.

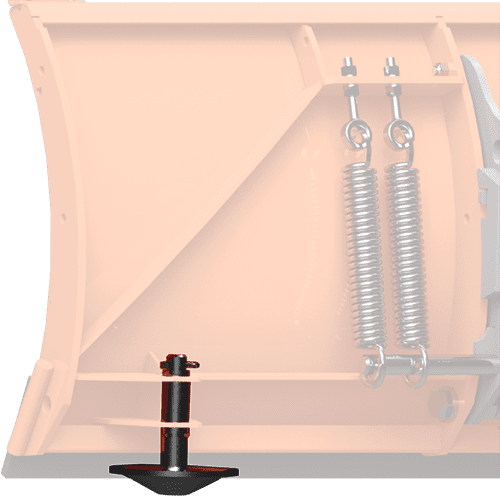

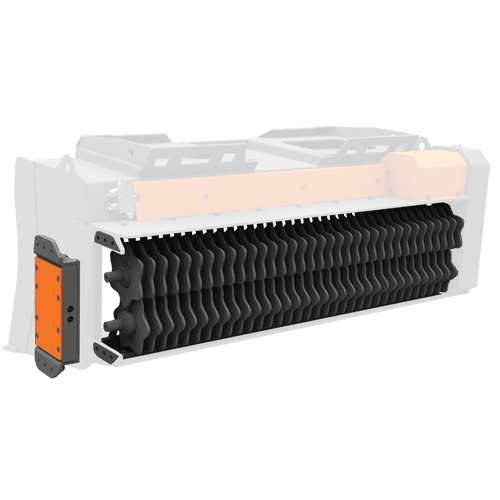

It is equipped with a collection tank with bolt-on reversible HB400 cutting edge, which makes the sweeper even more resistant.

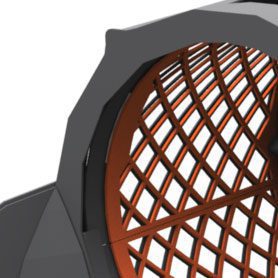

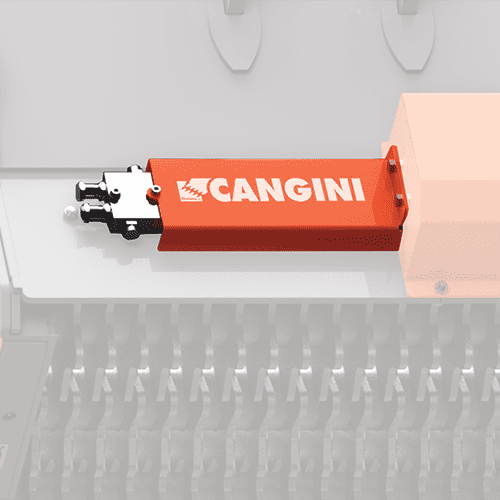

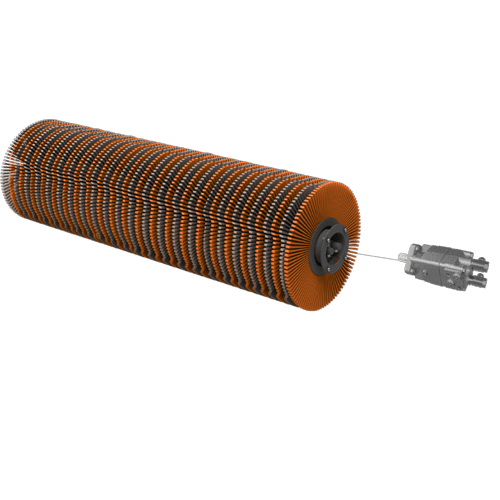

The SPZ sweeper is even more compact thanks to the shaft with integrated engine, which reduces its size and increases its ergonomics and visibility from the cab. The engine contained inside the frame gives it greater reliability.

It is extremely high-performance and durable, thanks to the robust frame and with bolt-on reversible HB400 cutting edge, which cleans deeply, removing even the most stubborn mud.

Even safer thanks to the internal anti-tip system and the addition of anti-slip footboards for entering the cab.

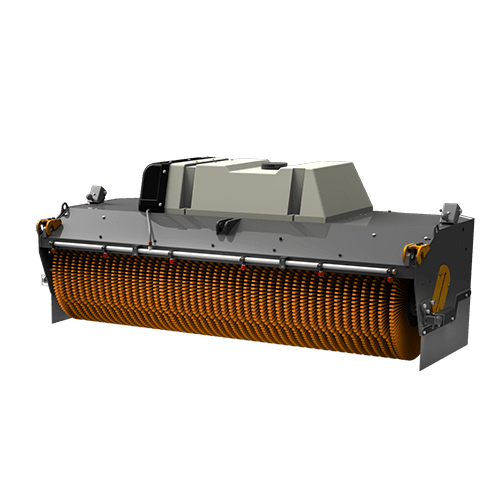

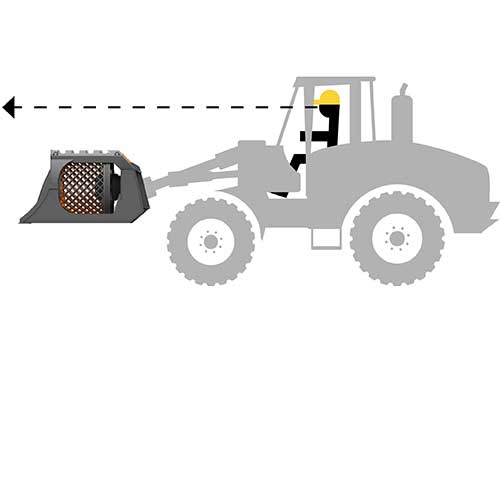

EASY TO HANDLE

More compact thanks to the engine without transmission parts. Size reduced by 10% for greater visibility.