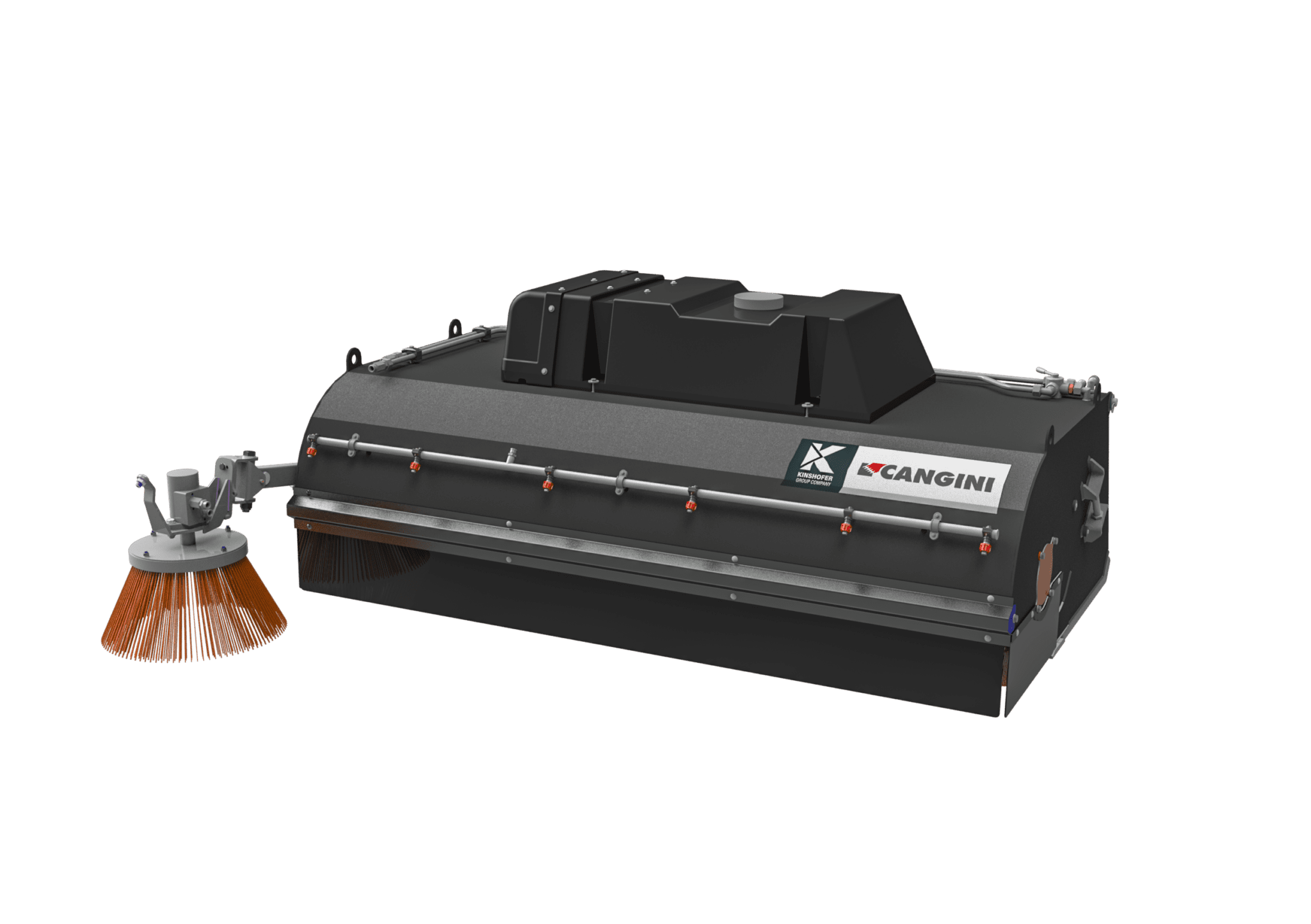

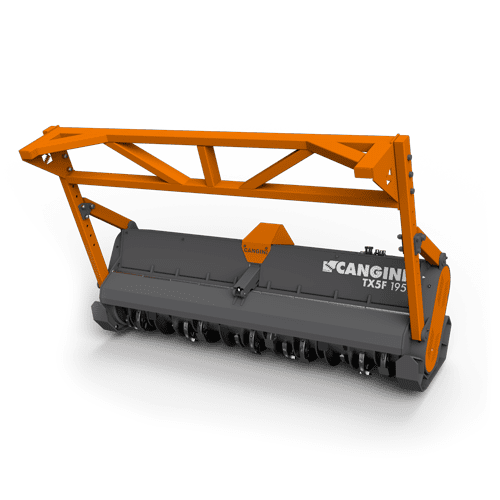

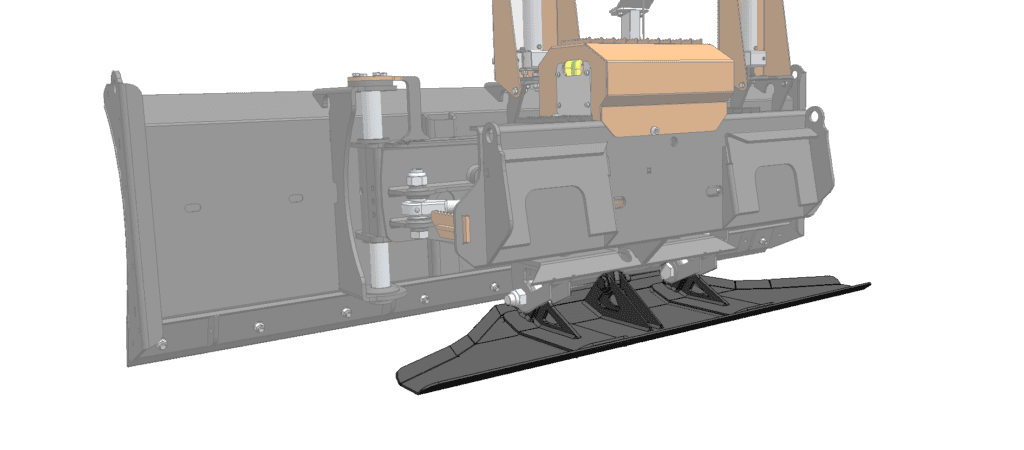

FRONT PALLET FORK

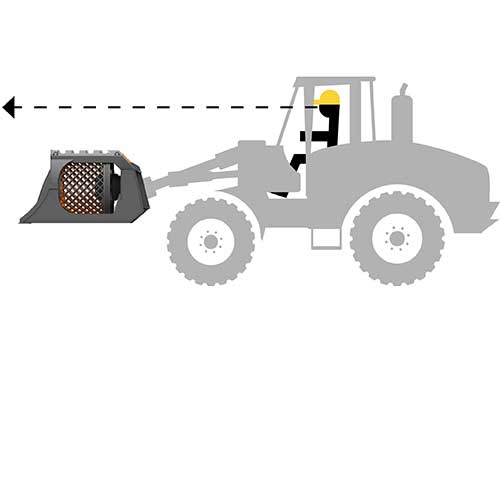

- Backhoe Loaders, Frontal Attachments, Skid Steer Loaders, Telehandlers, Wheel Loaders

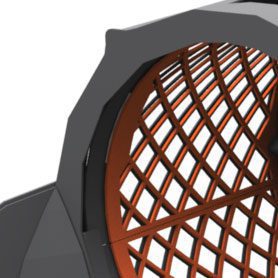

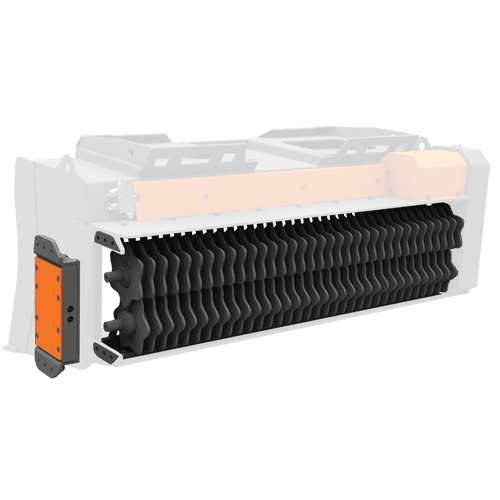

Pallet forks for lifting pallets in construction sites.

Especially useful in the construction sector, they are designed to handle palletized loads.

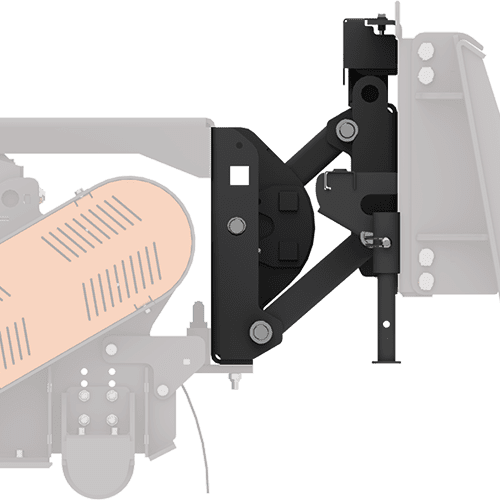

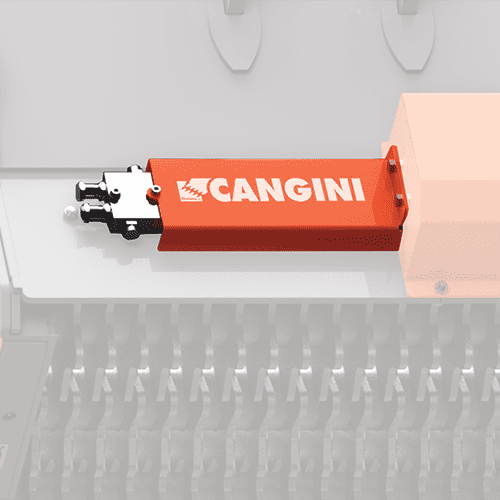

Available in 6 versions, Cangini pallet forks can be coupled to skid and mini skid loaders, wheeled loaders, telehandlers and backhoes..

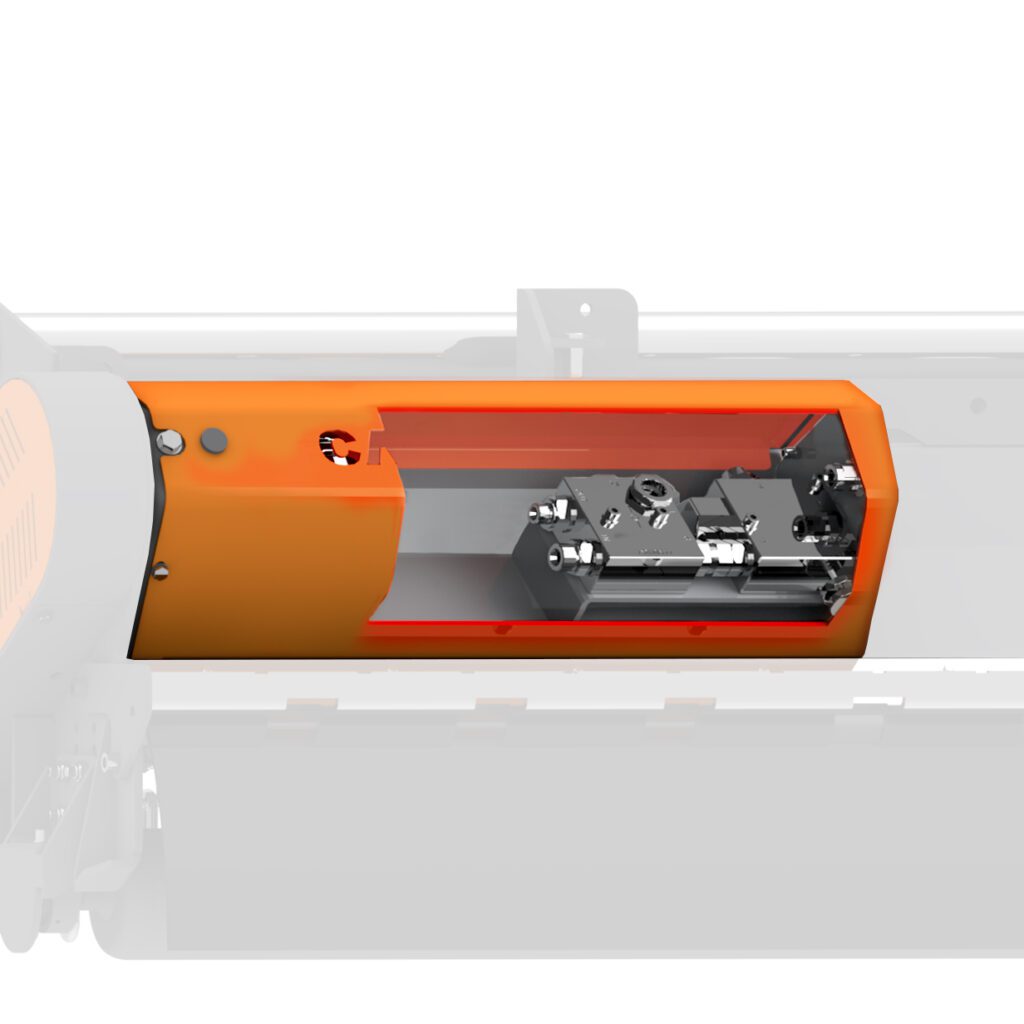

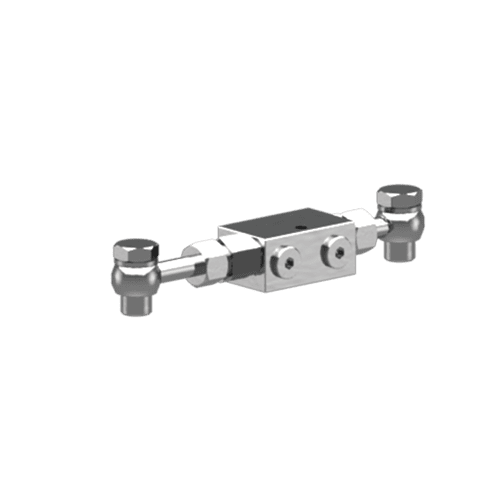

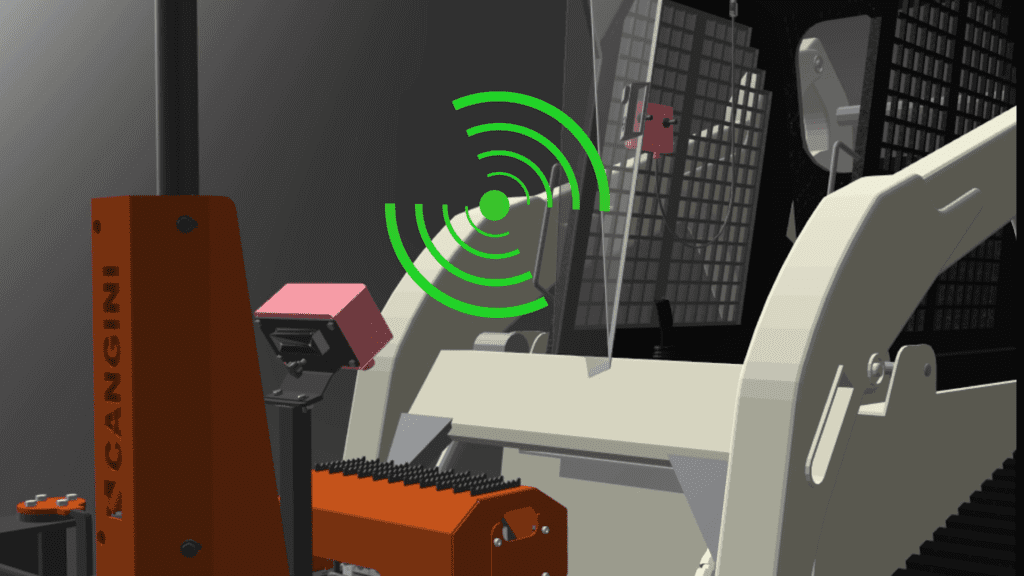

Rugged and reliable, they feature a safety system against load overturning during use.