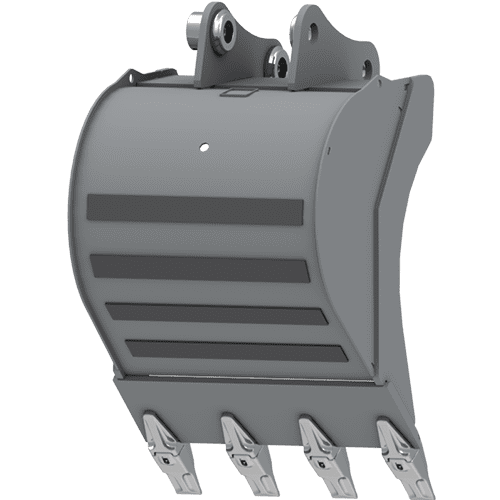

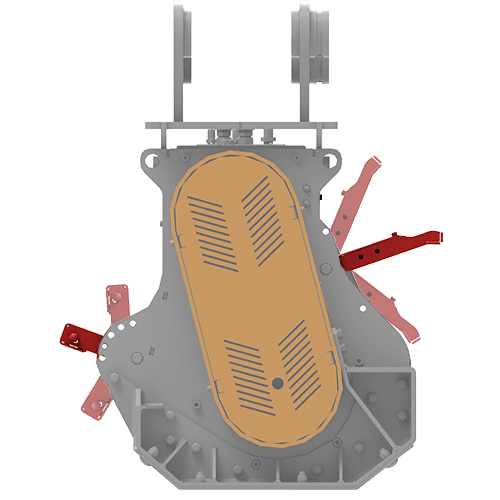

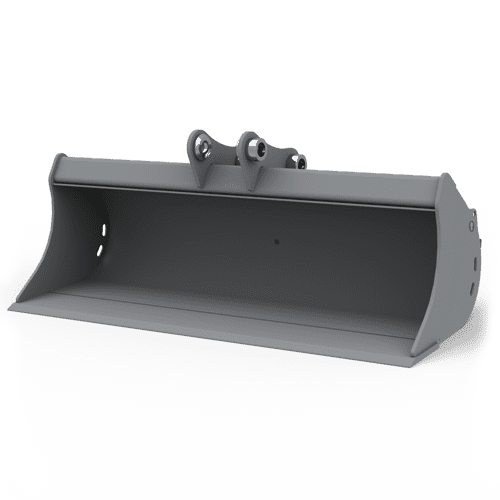

DITCH CLEANING BUCKET SP

- Backhoe Loaders, Buckets, Excavators

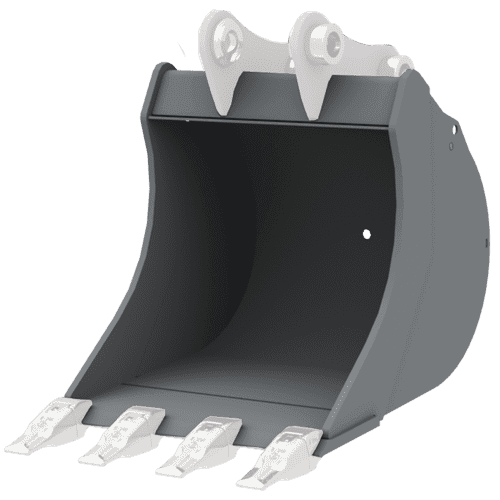

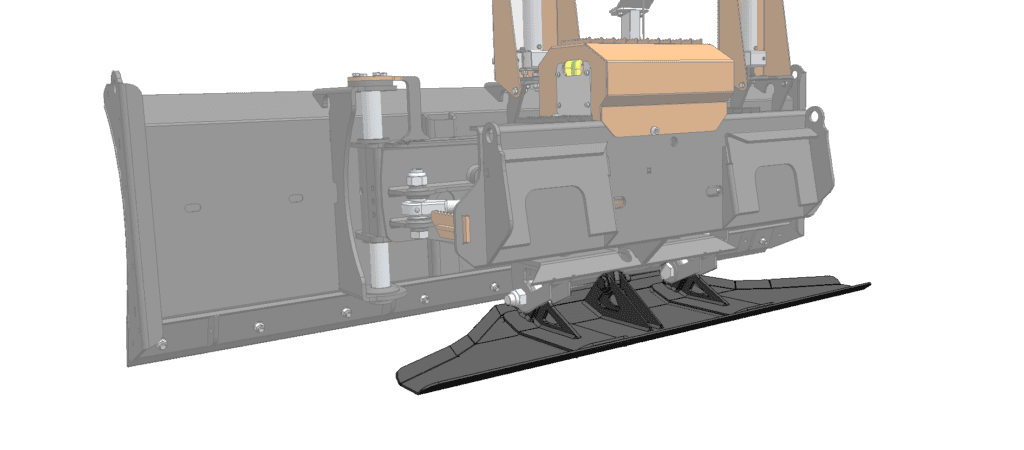

With its elongated, shallow form, the Cangini ditch cleaning bucket is the ideal choice for constructing and maintaining slopes, banks and ditches.

Ditch cleaning bucket is particularly suitable for :

- the cleaning, restoration and construction of slopes

- drainage ditches maintenance

- environmental reclamation works

- roadside maintenance

Thanks to the reinforcing bands welded to the bottom

- an area subject to heavy stresses,

- and the extra-hard cast steel teeth,

Its distinctive design ensures higher load capacity combined with more effective ditch bank levelling.

It has water drainage holes on the sides and bottom.

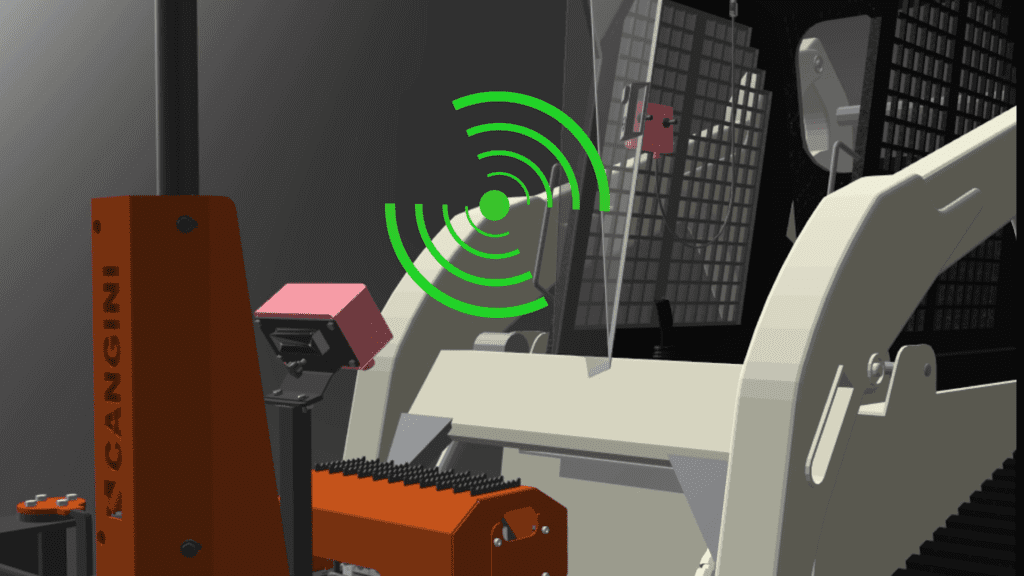

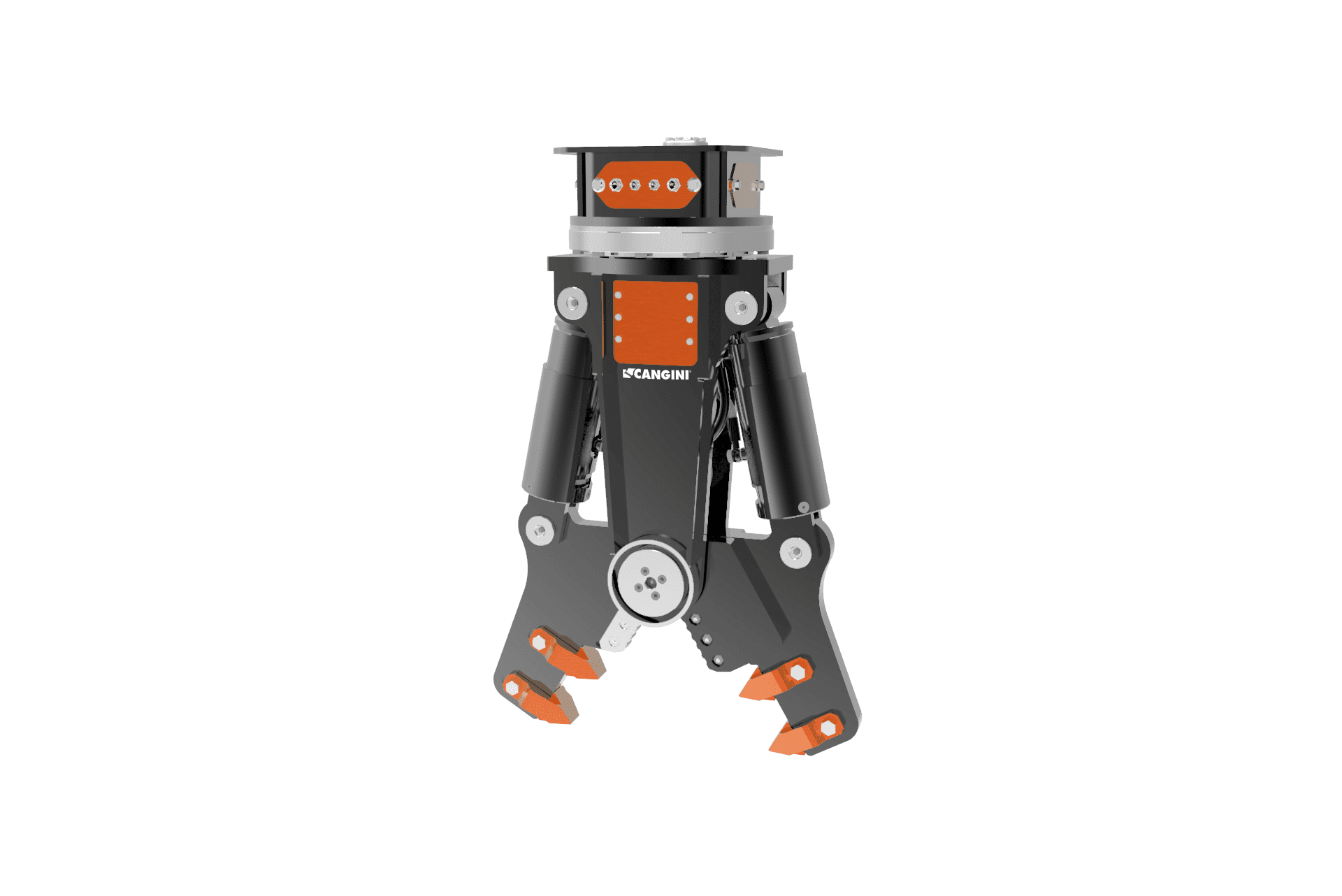

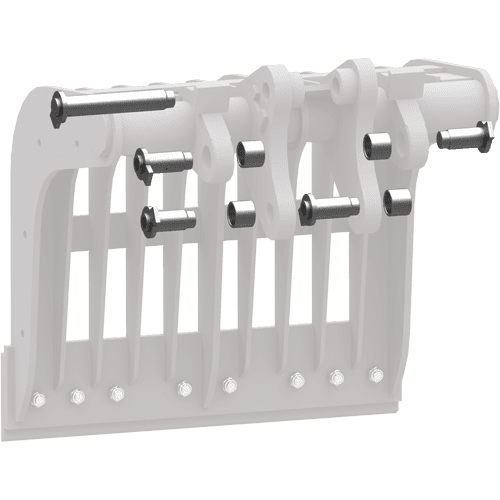

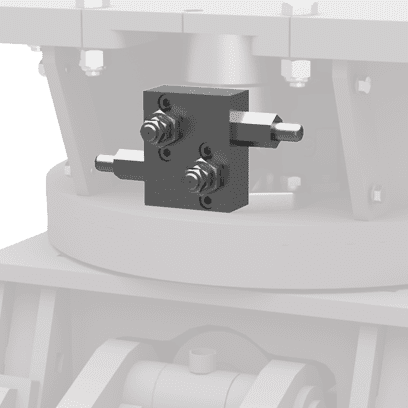

The advantages increase even more in combination with the Twist system, enabling the bucket to tilt up to 90° on either side, or Rototwist, allowing 55° tilt and 360° rotation.

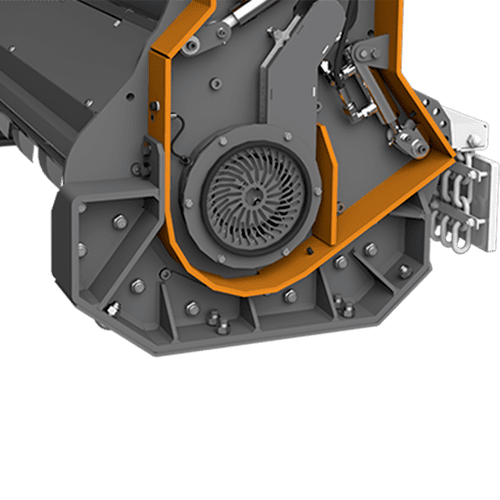

WEAR PROTECTION

The horizontal reinforcing bands safeguard the bucket from wear and increase its resistance.

Wide Range

The wide range of models allows the perfect match for every excavator, providing the best performance for each specific class and application from 1,0 to 22,0 ton.