Cangini Benne à Bauma 2025

Continue readingCR TWIN LOCK EVO : un pas en avant pour l’avenir du secteur

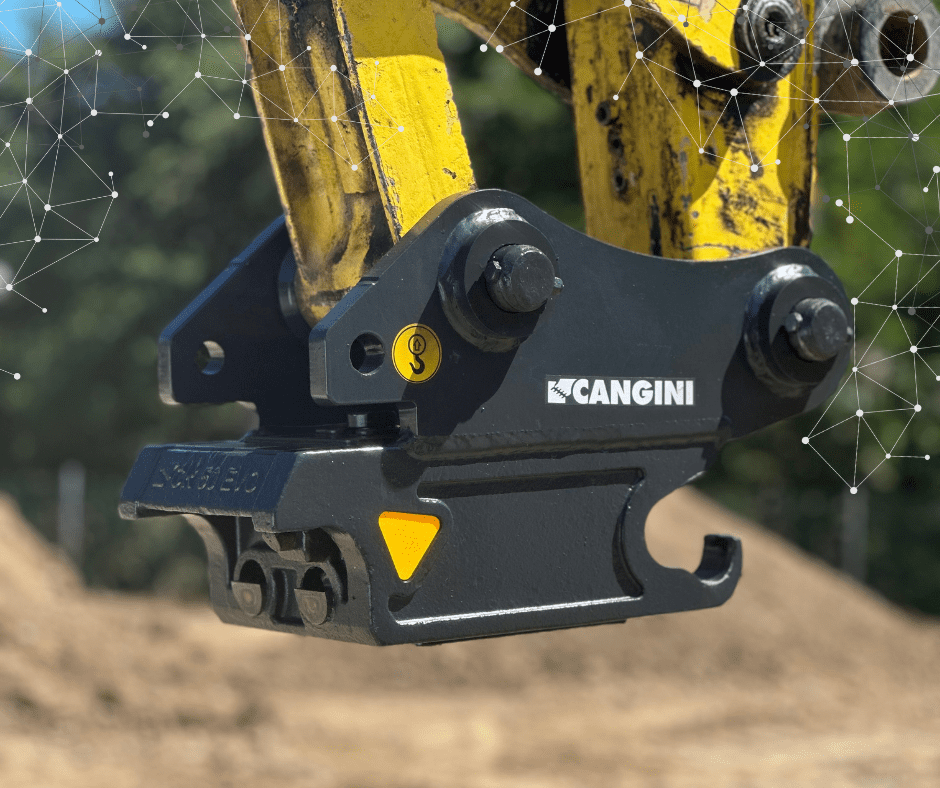

Nous avons le plaisir d’annoncer le lancement du CR TWIN LOCK EVO, le dernier produit innovant de la gamme Cangini. Après une longue période de tests rigoureux et d’essais sur le terrain, le CR EVO est prêt à remplacer son prédécesseur, le CR, qui est entré dans l’histoire avec plus de 69 000 unités vendues. Ce nouveau modèle intègre tout le savoir-faire acquis au fil des ans sur différents marchés et dans différentes conditions d’utilisation, et il est conçu pour établir de nouvelles normes d’excellence dans l’industrie. Le CR EVO est conçu pour offrir des performances supérieures, une sécurité avancée et une fiabilité exceptionnelle.

Principales caractéristiques du CR TWIN LOCK EVO

Corps en fonte à haute résistance

- Technologie de moulage avancée : le CR TWIN LOCK EVO est doté d’un corps entièrement moulé, utilisant des alliages métalliques à haute résistance qui offrent une solidité et une durabilité supérieures à celles des composants soudés traditionnels.

- Fiabilité et durabilité : le moulage augmente la résistance aux chocs et aux contraintes, ce qui garantit une plus grande durabilité et une réduction des coûts de maintenance.

Lubrification canalisée

- Système de lubrification intégré : Le CR TWIN LOCK EVO est équipé d’un système de lubrification canalisé qui répartit uniformément le lubrifiant sur toutes les pièces mobiles, réduisant ainsi l’usure et améliorant les performances.

- Maintenance simplifiée : ce système facilite la maintenance, augmente l’efficacité et prolonge la durée de vie du produit.

Visualiseur d’accouplement breveté – Contrôle visuel

- Technologie de visualisation unique : le CR TWIN LOCK EVO intègre le système Visual Check, une visualisation brevetée qui vous permet de vérifier l’état de l’amarrage rapidement et intuitivement.

- Sécurité opérationnelle accrue : le contrôle visuel permet à l’opérateur de vérifier l’accouplement directement depuis la cabine, ce qui accroît la sécurité et réduit le risque d’erreurs.

Systèmes de protection contre les chutes conformes à la norme EN 474

- Norme de sécurité actualisée : Le CR TWIN LOCK EVO est conçu conformément à la norme UNI EN 474, qui établit des mesures de sécurité pour éviter la chute d’outils pendant l’utilisation.

- Verrouillage sûr et capteurs : comprend des systèmes de verrouillage avancés et des capteurs automatiques qui garantissent que les outils restent fermement en place.

Avantages concurrentiels du CR TWIN LOCK EVO

Technologies exclusives

- Une innovation inégalée : Le CR TWIN LOCK EVO est le seul raccord rapide du marché à combiner des technologies avancées telles que le moulage à haute résistance, la lubrification canalisée, les systèmes brevetés Visual Check et anti-chute, offrant ainsi un avantage concurrentiel unique.

- Performance unique : ces technologies sont mises en œuvre conjointement pour améliorer la sécurité et l’efficacité opérationnelle.

Performance et efficacité

- Optimisation des opérations : La réduction des temps d’accostage et d’appareillage, associée à une lubrification efficace, améliore l’efficacité opérationnelle et réduit les temps d’arrêt.

- Durée de vie prolongée : des matériaux très résistants et une conception avancée garantissent une durée de vie plus longue du produit, réduisant ainsi les besoins de remplacement et de réparation.

Sécurité et fiabilité

- Conformité aux normes : Le CR TWIN LOCK EVO est conforme aux normes UNI EN 474, offrant une sécurité avancée pour réduire le risque d’accident.

- Contrôle visuel innovant : le contrôle visuel facilite les contrôles d’accostage, réduisant les risques et améliorant la sécurité.

CR TWIN LOCK EVO : un pas en avant pour l’avenir de l’industrie

Le CR EVO représente une avancée technologique significative pour les attaches rapides de pelles hydrauliques, combinant des caractéristiques telles qu’un corps moulé à haute résistance, une lubrification canalisée, un système Visual Check breveté et des mécanismes anti-chute conformes à la réglementation. Ce produit est la solution idéale pour répondre aux besoins modernes de l’industrie et se distingue clairement de ses concurrents. En choisissant le CR EVO, vous investissez dans un produit qui établit de nouvelles normes en matière de sécurité, d’efficacité et de durabilité.

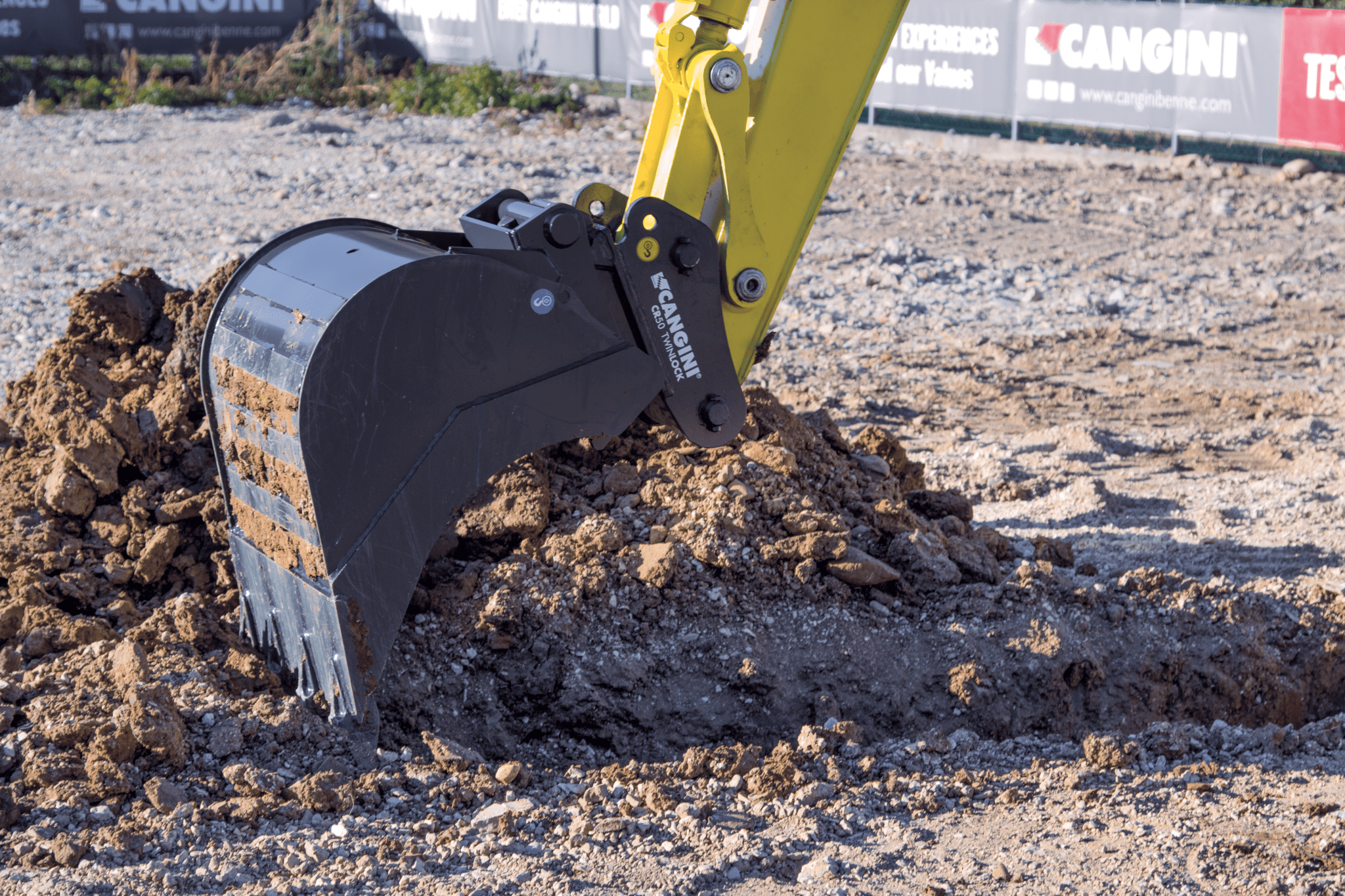

The right excavator bucket for your job? Cangini has the answer for you

Cangini has been manufacturing buckets for excavators, company’s core business, for over 30 years. They have always been a guarantee and a synonym for quality, as they are designed with materials that are designed to last and meet all the needs of professional users.

There are 26 types of bucket available in the catalogue to suit the application on all operating machines, thanks to the wide range with a total of around 300 models available.

Even for mini-excavators from 0.6 ton up to larger 22.0 ton excavators.

Here are the features of the Cangini buckets for your work on site!

By choosing a Cangini bucket you can boast of a service that aims at excellence, not only of the product, but also linked to the recommendation phase of our experts and the network of dealers at your disposal to advise you on the most suitable application for your needs in your daily work on the building site.

Strength, durability and reliability are among the basic requirements that the wide range can offer thanks to the choice of materials that are used in production and that are carefully selected at the design stage.

But lets now try to understand together how the different bucket models in the catalogue differ.

Buckets for all types of needs and excavators

The range consists of different categories of buckets, each of which has different characteristics depending on the type of work to be carried out:

STANDARD BUCKETS

This category contains the main buckets for your site operations:

- The ideal digging and ditching bucket

- Ditch cleaning bucket can be swivelled for working near banks and canals

Both of these versions are available in a reinforced variant that features reinforcement strips and side cutters if heavy-duty operations are required.

- The skeleton bucket which, thanks to its grates, allows the sorting of stones and aggregates

- The trapezoidal bucket which with its trapezoidal shape is suitable for narrow excavations

SCANDINAVIAN BUCKET

This type of bucket is particularly popular in Scandinavian countries; it prevents soil from adhering to the walls and ensures that the material is discharged. They are differentiated by the abbreviation GD general duty and HD heavy duty. The HD version is particularly suitable for working on rocky, compact and abrasive soils and therefore tackling heavy work.

Also in this category we find buckets suitable for different types of work:

- Excavation and earthworks

- Cleaning of ditches, banks and canals

- Sorting stones and aggregates

- Cable bucket with a narrower and longer profile, optimal for burying cables, pipes and for precision digging.

NETHERLAND BUCKET

The Netherlands bucket category consists of five models that are particularly popular in the Netherlands area. Their profile prevents soil from adhering to the walls, ensuring the unloading of clayey and wet materials.

Also in this category we find buckets suitable for different types of work:

- Excavation and earthworks

- Cleaning of ditches, banks and canals

- Sorting stones and aggregates

- For burying cables, pipes and for precision excavations

About the range: Discover it at upcoming events!

The forthcoming trade fairs will be a great opportunity to showcase our ever-expanding range across several sectors.

We will soon be present at the Las Vegas trade fair from 14 to 18 March and then at the Samoter international trade fair in Verona from 3rd to 7th May 2023.

we are waiting for you

‘We create value together’: our achievements in this 2022

A year marked by a difficult macroeconomic context is coming to an end.

Despite the uncertainties of the market, Cangini Benne has shown flexibility in adapting to changes in the market to ensure the continuity of its products and to satisfy consumers.

Davide Cangini (Managing Director of Cangini Benne) thus shares some thoughts about this year just around the corner:

« What balance do you feel like drawing at this point in the year? »

« Despite the macroeconomic picture in 2022, marked by strong inflation and a contracture in the various European markets, we can still confirm the high level of interest in the range. As far as demand is concerned, although there have been some shifts, we are closing with a positive balance. We expect to close the year with about +23% compared to 2021,’ says Davide Cangini.

» What is the reason for the company’s success to date? »

« Certainly the results we have achieved have not been achieved through the efforts of one person alone, but thanks to the ideas and skills of a large team; this is how we manage to create value for the company.

My goal is sustainable growth, which is based on production innovation and resource optimisation to ensure high standards of product quality and reliability.

I like to think that the value of an idea lies in knowing how to put it into practice, and we are able to do that. ‘ Cangini continues.

« What are the forecasts for the new year? »

« For this 2023 I expect a market downturn that will push companies to further optimise their resources, a segment on which we have already been working for some time in order to maintain a high level of competitiveness. As far as Cangini is concerned, we will continue to invest in research and development to improve product performance and ensure high safety for the customer. » He concludes.

A global reality that also this year sees growing numbers for equipment sales which are up +31% and an increase of +27% on quick couplings and +24% on buckets.

After Bauma: expectations achieved!

Meeting and sharing were at the heart of this long-awaited event, which ended with all positive numbers.

A frenetic stand that, for the entire seven days of the fair, welcomed many visits that ended with a request for an offer. This meant that the strong networking activity, together with the high media impact, played a key role in the overall outcome of the event.

Many potential dealers, from various parts of the world, expressed their interest in the products and service offered, willing to start a partnership with the company.

A successful comeback for Cangini’s team

Bauma was a success for Cangini, which can confirm the continued interest in its entire range, which is increasingly expanding, from established products to those newly added to the catalogue.

And it was precisely at Bauma that the company demonstrated this ongoing expansion. The products previewed were placed in the spotlight to great acclaim.

The result of the R&D department’s innovation was the prototype VRC screening bucket, which with its new, cleaner profile and shaft distribution for higher productivity and loading capacity, charmed many users who stopped by to ask for more information.

Evo-lution serie

Added to the above products are the new EVO version quick coupler, which aim for greater safety. The new version features a coupling and locking system that allows visual assessment of the coupling status.

With this configuration it is possible to check directly from the cab if the quick coupling has correctly completed the coupling phase. In this case a dual display system informs the operator when the quick coupler has fully engaged with the adapter.

The new yellow, triangular-shaped ‘Safe Check’ side visual indicator allows full control of the coupling status, while the front indicator allows the same to be checked directly from the cab. Added to this is the double fork’s profile , which amplifies the safety concept by preventing the risk of the tool accidentally falling off.

We are Cangini : Commitment, passion and dedication

« We couldn’t be more satisfied, the Bauma trade fair gave us the opportunity to meet long-standing customers but also many potential dealers from all over the world. This allowed us to compare ideas and gather insights for continuous improvement. » The words of Davide Cangini.

« All the Cangini staff with commitment and dedication contributed to the excellent result of this event, so my thanks go to the whole team, both those who were on site but also all those who from behind the scenes collaborated and made this result possible ».

Cangini Benne gives way to evolution!

The company is introducing a new series of advanced and innovative quick couplers to face construction sites with more safety and efficiency.

Cangini’s wide and reliable range of quick couplings finds its progress with the introduction of the EVO SYSTEM version, directly linked to an evolutionary concept that matches some historical models, in the catalogue since 1989 and widely appreciated by the market.

All about safety

Added value of this new system is linked to the concept of safety.

The new version of quick couplers meets the new safety regulations required by Machinery Directive.

The new version features a coupling and locking system that allows visual assessment of the coupling status.

With this configuration it is possible to check directly from the cab if the quick coupling has correctly completed the coupling phase. In this case a dual display system informs the operator when the quick coupler has fully engaged with the adapter.

The two visual elements are positioned laterally and frontally.

The new yellow, triangular-shaped ‘Safe Check’ side visual indicator allows full control of the coupling status, while the front indicator allows the same to be checked directly from the cab. When the indicator is no longer visible, the pins are properly engaged.

The EVO system has an additional feature the fork’s double profile

that prevents the risk of the tool accidentally falling over the entire stroke, up to an angle of 30°.

Its shape allows the tool to be released once it is placed on the ground.

An ever-growing range that proves to be a winner when it comes to safety.

The extensive range presented at Bauma in Munich

Ahead of the international Bauma trade fair to be held in Munich from 24 to 30 October, Cangini is enthusiastically preparing to welcome its visitors to an environment that favours the exchange of ideas and innovation.

« Our expectations? To meet again the European customers with whom we have always had an important partnership, and at the same time to make new potential meetings to strengthen and extend business in new markets. It will also be an opportunity to give space for discussion, listening to the needs of users and professionals in the sector, with a view to continuous improvement,’ these are the words of CEO Davide Cangini in anticipation of the next edition. « What you will see on display at the fair is the result of the efforts of the entire Cangini team and our constant investment in Research and Development that has resulted in the products that will be on show, » he continues.

Here is what you will find at the fair!

The company is ready to present its ever-increasing range of innovative and up-to-date products.

All product categories will be present: buckets, quick couplers and attachments, from green maintenance to road maintenance, construction, forestry and screening.

The Bauma showcase will feature some preview products, not yet launched on the market, which will enter the catalogue at the beginning of 2023.

Among them, Cangini’s range of quick couplings, company’s core business, has also evolved with the launch of a new series of couplings that anticipates the demands of new safety guidelines.

As far as the screening machine range is concerned, there will soon be the entry of a new model that optimises the features of the screening machine now on the market, designed to facilitate the screening operation and have higher productivity.

In addition to these are the historical products that over the years the engineers have helped to improve in order to listen to the needs of its users with the aim of optimising performance while simplifying work on site.

And even more news are waiting for you!

Cangini Benne will be in Hall C.5 at stand 149

Cangini suggests you the most suitable equipment !

How to choose the right mulcher for your needs? This article can help you.

Continue readingCangini Benne awarded among the 100 Italian Excellences. « Proud of the progress made so far and ambitious about the steps for the future »

On Thursday 16th December 2021, Cangini Benne was awarded by the Committee of Honour, in the renowned „Sala della Protomoteca“ in Campidoglio, Rome, for the VIIth Edition of the 100 Italian Excellences Award.

Continue readingINTERNET OF THINGS “WHOEVER THOUGHT THIS UP IS AN INNOVATOR“

It has never been so crucial as nowadays to stay abreast of the times in order to make the most of the benefits brought by technology to optimise the quality of work.

Cangini’s continuous approach to innovation is now a proven fact. However, this tendency to innovate and the constant development is balanced between tradition and future.

Tradition: because the values and principles have not changed, as well as the aim of always improving in order to supply safe products that last over time, so as to satisfy all the needs of the market, which is still growing.

Innovation, because it is necessary to catch every signal from the market and every evolution in order to keep up with the times. Cangini has always demonstrated its commitment to this, working with dedication and investing in its Research and Development department, which has always been an important part of the company’s success. Discovering the most advanced technologies to be applied to products.

A cutting-edge example is the recently launched system: IOT (internet of things) applied to the X-Plane laser blade. The Internet of Things solution is based in a cloud and a wireless communication. It enables easy, secure and scalable connection of physical objects – IoT devices and computer-based systems. This unique environment makes connected external reality ,allowing data from IoT devices to be gathered, stored. This technology is the solution for a digital market challenges.

Through this system, the company can provide remote assistance to intervene promptly to correct and improve operating parameters. In addition, the operator will always be informed of the routine maintenance operations to be carried out, which will also be communicated by e-mail.

It is also a matter of increased safety for the operator and the equipments.

Since the launch of this new equipment, the market and customers have shown significant interest.

Above all, the rental companies have recognised the enormous potential and functionality of the equipment. This is an epic change that can make work easier and provide timely and reliable data on the health and activity of the equipment. The desire is to move out of the comfort zone and get into a new era of equipments that will allow it to be even more competitive on the market.

Connectivity is becoming the future of equipment management and appears to be fundamental to making equipment safer and more reliable.