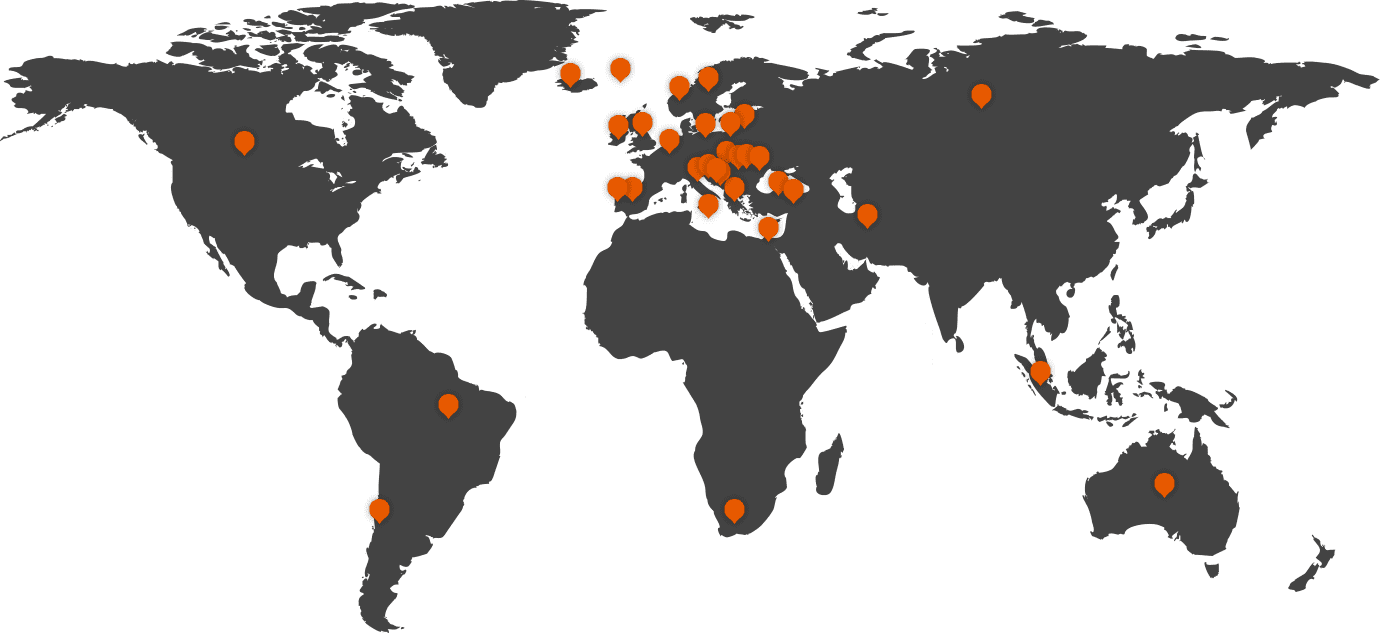

Exports to 40 countries in the world

WE DESIGN EXPERIENCES AROUND OUR VALUES

INNOVATION

Innovative boost is the core of our work. We are always focused on researching innovative solutions, in order to make our customer’s work ever more efficient, safe and productive.

TRUST

Those who we work with can rely on us and on a strong and reliable partnership. We are consistent and keep to our commitments.

EXCELLENCE

We control each phase of the production process first-hand. This is the reason why 100% of our products are manufactured in Italy. We cultivate excellence in our staff, our products and our processes, with no compromise.

CANGINI’S WORLD

Our success is the result of everyone’s involvement, because the most innovative ideas are born out of passion and teamwork, and they can only be achieved thanks to everyone’s commitment.

SAFETY

We design out projects according to the final user’s needs. We prioritize safety and commit to supplying safe and long-lasting equipment to our customers.

TERRITORY

We maintain strong bonds with our territory and we actively contribute to its cultural growth and to the social well-being of the community.